Custom Thermal Transfer Labels: Durable and Weatherproof Printable Roll

In a world characterized by quick impressions and briefprints, there is a sense of continuity in the art of permanence. Thermal transfer labels are an important part of labeling and printing with barcode systems today. They are used in manufacturing, logistics, health care, and retail, and provide outstanding quality printed labels with durability for both short and long-term use.

Thermal transfer labels have emerged as an essential resource for organizations wanting a long-term and dependable way to label goods.

But how do you know that your current labeling system will meet your needs? Is your organization exposing itself to expensive errors or inefficiencies through fading, smudging, or illegible labels?

Now is the time to ask yourself if you are confident in the labeling process you currently use. Is your organization competent enough for the future?

"Are you tired of faded prints and smeared barcodes?

Experience a clear and durable presentation on any surface and under any condition."

Unlike direct thermal labels that utilize heat-sensitive coatings, thermal transfer labels transfer images with a ribbon process. The images are permanent and more resistant to smudging.

LabelPouches is a specialty supplier of high-quality, durable labels that contribute to the brand perception of your products, backed by performance that lasts. From products and assets to packaging, our customized labels will ensure that everything is in bulk quantities that fit your demand. Our high-end thermal transfer custom labels offer you a higher level of quality, clarity, reliability, and professionalism.

Because your brand deserves it!

What Are Thermal Transfer Labels?

Thermal transfer labels refer to labels that are intended to be used with thermal transfer printers. In these printers, the thermal ribbon is used to transfer ink onto the surface of a label/or printed bands. When the thermal print takes place, the heat from the thermal transfer printer will melt the ink, causing it to become attached to the printed label.

This process provides resistance to fading, smudging, or rubbing off, which is important in working situations like rough or long-lasting labeling.

They are available in paper, polypropylene, and polyester substrates for environments needing high performance. Labels pay off for your products- from manufacturing and logistics, to food, beverage, and healthcare. If you are connected to any of the above businesses, you can use thermal transfer labels for your operation. Longer shelf-life gives a better competitive advantage to your product.

How Custom Thermal Transfer Printing Works

Customization is what gives your product its unique identity in a saturated market. A standard thermal transfer printing system involves the following steps - all of which are crucial to achieving your desired results.

Label Stock

The base material (made from either paper or synthetic) that accepts the printed image. The label should be long-lasting and smudge-resistant.

Thermal Transfer Ribbon

A coated film that contains solid ink, usually made from a combination of wax, resin, or both.

Printhead

The heat element that raises the temperature to transfer the ink from the ribbon to the label.

Printing Process

The ribbon and the label stock are fed simultaneously into the printer. The printhead heats the ribbon to predetermined areas based on the image/text data. The melted ink will then be transferred onto the label surface and immediately set. The used ribbon will wind around a take-up spool, and the printed labels will exit the printer.

Moisture-free and Tear-resistant Label Materials Options

There are various materials for thermal transfer labels:

Paper Labels

Paper is a cost-effective material for indoor use, with a shorter product life when used with indoor products. Paper is a versatile labeling facestock which will adhere to a wide range of surfaces such as corrugate, paper, packaging films, and (most) plastics and metal & and glass.

Affordable and appropriate for applications like shipping and retail labeling.

Synthetic Labels

Similar to paper, synthetic materials offer labeling options for many different surfaces. But the benefits of a synthetic label over paper are its durability and attributes regarding the environment. This indicates a longer lifecycle of the label, the ability to withstand an outdoor environment, and resistance to abrasions, moisture, and chemicals.

Synthetic labels are referred to as poly and come in four variations of poly, which are the material types. The main differentiators of the materials are outdoor exposure, temperatures, and facestock color and treatments.

Polyolefin

Polyolefin will stand out for curved and rough surfaces and has an outdoor exposure time of up to six months.

Polypropylene

Polypropylene has an outdoor exposure time of one to two years and will flex for curved surfaces.

Polyester

Polyster is good for high temperatures, rated to 300°F (149°C) with outdoor exposure of up to three years.

Polyimide

Polymide is also good for high temperatures, rated to 500°F (260°C), and is recommended for circuit board labels.

What Makes Thermal Transfer Labels Different?

Thermal transfer labels are designed to last, unlike generic labels that can fade or suffer any number of damages over time. The process for making them involves a heat-based printing method. This method allows the ink (from a ribbon) to be transferred onto the label surface, resulting in prints that are:

- Sharp and clear, even for small barcodes

- Resistant to wear, never smudged, never faded, never missing information.

-

Ready for extreme environments, Freezer? Hot warehouse? A shipping box that travels halfway around the world? These small yet mighty carriers of information provide identification for your products: they tell the story of your brand with clarity, adherence, and style.

It's the difference between a label that just "sticks" and a label that strengthens your operations.

Thermal Transfer Labels Vs Direct Thermal Labels

Labels are the most vital part of the product. In the market to stand out and have good sales with updated inventory, you need a scannable label that shows all the basic info about the product. There are two types of labels, thermal transfer label and direct transfer label. Let's discuss both:

Thermal Transfer Labels

Thermal transfer labels use a ribbon that produces heat to melt ink onto the surface of the label. This also provides durable, quality prints that are not easily scratched, smudged, or faded under normal circumstances. This makes them a good choice for long-term applications that will be used in extreme environments.

The durability of the thermal transfer label provides the same readability after use, allowing the label to remain intact for months or years. This makes thermal transfer labels the label of choice for inventory tracking, product labeling, or other demanding applications.

Direct Thermal Labels

Direct thermal labels are printed by using heat to activate the adhesive feature of the label. There is no need for ink or a ribbon. Direct thermal labels are budget-friendly and work best for high-volume, short-term use labels such as shipping labels, tickets, and receipts. Since the print on a direct thermal label relies on heat to generate the print, the print is more prone to fading over time.

Direct thermal labels lose the most print when exposed to heat or sunlight, resulting in labels. That will fade over time regardless of their surrounding environment. Direct thermal labels are appropriate in an application where the labels will not be exposed to extreme conditions.

In a nutshell, direct thermal labels can lose the print, while the thermal transfer labels are more reliable and work great for your product in any industry. We always recommend that you use thermal transfer labels if you want to save money and get more durability.

Why Will Your Business Love Thermal Transfer Labels

Any business is always in search of durable and long-lasting materials to depict their brand. Thermal transfer labels are not the labels; they are the representation of your brand.

Protect Your Reputation

If your labels fade while in transport or storage, your customers are less likely to trust you. Thermal transfer labels ensure that your brand looks professional from start to finish.

Save Your Money

Even a small amount of time or material wasted on printing labels multiple times, unreadable barcodes, or fixing shipping errors eats into your profits. With thermal transfer labels, you avoid a lot of these issues because they are made to work.

Flexibility

They work in every business sector, from retail and e-commerce packaging to labeling healthcare products and identifying logistics tracking to frozen foods.

Build Your Brand Identity

Your labels not only provide value, they're also a promotion. You can add logo, colors, designs, etc., to your label and allow your label to do double duty

A Quick View of The Areas They Excel In

There are various industries in which labels are used and are in high demand. Every industry prints basic and important information about the product.

|

Industry

|

Typical Uses

|

|

Manufacturing

|

Product ID labels, component tracking, equipment labeling

|

|

Logistics & Warehousing

|

Shipping labels, pallet labels, barcode tags

|

|

Healthcare

|

Specimen labeling, patient wristbands, and lab samples

|

|

Retail

|

Price tags, shelf labels, and inventory tracking

|

|

Electronics

|

Circuit board and component identification

|

|

Chemical & Industrial

|

Drum labels, safety labels, outdoor asset tags

|

Types of Thermal Transfer Ribbons

There are 3 major types of thermal transfer ribbons that are widely used.

|

Ribbon Type

|

Composition

|

Key Features

|

Best For

|

|

Wax

|

Wax-based ink

|

Economical; suitable for paper labels; moderate durability

|

Shipping, inventory, retail labels

|

|

Wax/Resin

|

Blend of wax and resin

|

Higher durability and smudge resistance

|

Product identification, healthcare, logistics

|

|

Resin

|

100% resin ink

|

Maximum resistance to chemicals, heat, and abrasion

|

Industrial, laboratory, and asset tracking labels

|

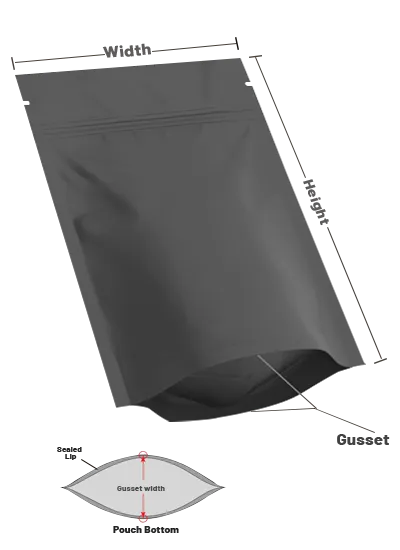

Standard Sizes: Choose The Perfect Size for Your Packaging

Labels can be categorized into 3 basic types: small, medium, and large. Although there is always an option to get a custom sizing and design for your product.

|

Standard Sizes of Thermal Transfer Labels

|

|

Size Category

|

Size

|

Common Uses

|

| Small |

1 x 0.75 |

Small applications (e.g., jewelry, electronics) |

| 2 x 1 |

Small product labeling, barcode labels |

| Medium |

3 x 2 |

Product labels, asset tracking, retail labels |

| 2.25 x 1.25 |

Small barcode labels |

| Large |

4 x 6 |

Barcode labels, packaging |

| 4 x 4 |

Large product labels, shipping, and inventory tracking |

| Custom Size |

Varies |

Custom sizes for specialized applications |

Why Choose LabelPouches: We Help You Tell Your Story

At LabelPouches, we understand that a label is not just a piece of material. It represents your brand, your values, and your promise to your customers. That is why we not only sell labels but also create solutions that help businesses convey who they are. Labels differentiate their products and successfully respond to real-world challenges.

LabelPouches, where every label is a mark of quality that lasts.

What Makes Us Different

No two brands are alike, and appropriating labels for yours shouldn't be either. Whether you’re looking to create a moisture-resistant label for a beverage, want stability for frozen, or pure prestige for luxurious, we will create a crafted solution for you.

Expertly Tested For Durability

All labels are built for toughness. Each design undergoes a set of tests for quality and performance. From the warehouse floor to the retail shelf, labels maintain clarity and adhesion.

Creativity Meets Real-world Applications

We meld our artistic identity with our technical expertise. This synergy brings you labels that capture your brand's spirit while adhering to all regulatory, functional, and logistical requirements.

Timely, Reliable, On-Time Delivery

We know that timing is the essence of your business’s success, which is why we have efficient production schedules, responsive service, and on-time delivery.

Sustainability Options

Eco-friendly and sustainable paper and inks to support your brand’s commitment to the environment.

One-stop Solution

We can design, print, and produce your labels all under one roof.

Industry Knowledge

We have a decade of experience in the packaging of food, beverage, healthcare, and retail, to know what works for your market segment.

Scalability

Whether you need a hundred labels or volume printing, we have the flexibility and capacity to provide you with your desired quantity.

Order A Free Quote NOW!

Let's hold hands and grow.

We provide personalized thermal transfer labels at wholesale rates for bulk production with your logo, colors, and messaging. No need to try advertisements or pay influencers; our down-to-earth labels act as your product ambassadors.

Don't rent a booth, click, or mail flyers. If you want to kickstart your company with a high-quality thermal transfer label that will last, contact us today to receive your custom quote.