Custom Retort Pouches: FDA-approved, Flexible, And Recyclable Packaging

Retort pouches or Retortable pouches are a significant upgrade in food packaging. This has changed the market of food processing, marketing, and distribution. In a time of increased demand for convenience, shelf stability, and sustainability, flexible packaging solutions like retort pouches are gaining momentum as a prominent choice.

What if you have a baby food business specifically, and you are more concerned about the quality remaining the same, but HOW?

All of the trust of parents or working individuals who have less time to prepare special mineral-rich food for their babies, they put trust in your brand. Why would you want to lose that trust?

There comes the Retort pouch packaging, which entails a blend of specialized material and advanced thermal processing. It is known to have numerous advantages over packaging alternatives such as cans and glass jars. At LabelPouches, we provide custom pouches with various personalization options, such sizes, styles, designes, printing, and finishing.

What Is A Retort Pouch?

A retort pouch is a type of flexible pouch that consists of several layers of material. They are specifically designed to withstand the high heat required for the retort process. It has been processed in a pressure vessel called a "retort".

The pouch consists of polyester, aluminum foil, and polypropylene. The food is sterilized at high temperature, normally in the range of 240°F to 250°F (115°C to 121°C), and can be stored at ambient temperature. The retort process requires pouches first to be filled with food and then, in a sealed pouch.

Retort pouch packaging is commonly used for pre-cooked food and beverages, and is an alternative to can manufacturing methods. They can be designed for hot or cold filling because of the unique design of the pouch, making retort pouch packaging surprisingly versatile. This guarantees:

1. Elimination of bacteria for product safety

2. A shelf life of 6-24 months with no refrigeration

3. Flavor, texture, and nutrient retention

Why Retort: Has There Been a Revolution in The Market?

Retort pouches were first developed in the 1960s to provide lightweight and compact packaging with the capability to retain flavor, nutrients, and texture.

The concept for retort pouches grew out of the need to preserve foods to be used in the military, the space program, and the Vietnam War. In 1963, a US company, Flexi-Seal, got a patent to develop a retort pouch to be used for the purpose of preserving and transporting food without the bulk of a can.

In the 1970s and 1980s, processing foods with retort pouches came to the commercial marketplace, especially with ready-to-eat meals along with soups, stews, and sauces. Soon, they became popular because of their lighter weight for storage and their better features of preserving food with better materials than cans.

By the end of the 20th Century, retort pouches were distributed in many products, including military rations (MRE - Meals Ready-to-Eat) and convenience foods in grocery chains in many supermarkets. Instantly, these custom printed pouches gained a foothold in pet foods, baby foods, and drinks on store shelves. As of now, they are prevalent in the food industry as the most eco-friendly packaging, featuring an alternative to glass jars and metal cans.

Why not upgrade your product? Let’s take your business to new heights with greater ROIs and branding.

Retort Pouch Composition

Retort pouches are packaging formats that are composed of multiple layers of materials such as polyester, foil, and polyethylene. The materials can be combined to provide good combined barrier characteristics in order to protect contents from moisture, light, oxygen, and spoilage. The layers also work as a vacuum sealer. The primary layers are:

1. Outer Layer: Often made of a strong package like PET (Polyethylene Terephthalate) or Kraft paper, this layer contributes strength and durability to the retort pouch.

2. Middle Layer: This layer is typically made from a metal foil or multi-layered foils (e.g., Mylar) and serves as the primary barrier for light, moisture, and oxygen impact.

3. Inner Layer: This layer is typically made from food-safe polyethylene that performs as a sealant for the contents to create an airtight seal.

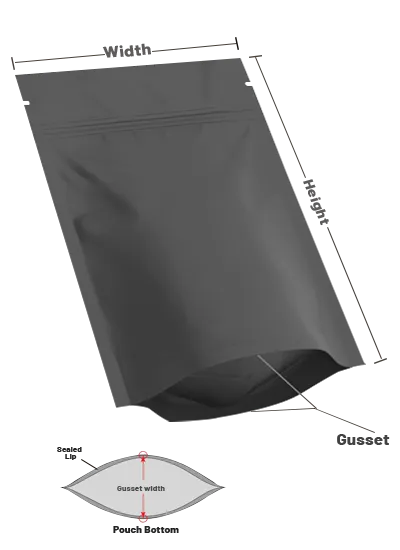

Some retort pouches include gussets, which can allow the pouch to stand on display shelves when filled. At LabelPouches, this retortable bag design not only increases sales but also provides convenience for use.

Layers That Make Retort Pouches Work

Polyester (PET): Strength and printable surface

Aluminum Foil: Barrier to oxygen, moisture, and light

Polypropylene (PP): Heat-resistant, food-safe interior

Optional Nylon: Adds puncture resistance

The Retort Process: Thermal Processing For A Longer Shelf Life

One of the most distinguishable features of retort pouches is their capacity to endure high heat during the retort process, where the pouches are placed in a retort (a large pressure cooker) for sterilization. Thermal processing efficiently destroys bacteria and any other microorganisms, so the food can remain safely edible without refrigeration. This process is achieved using a combination of high heat and pressure, both creatively distributing heat evenly to the food and transitioning it into a sterile, packed product.

In addition to extending the shelf life of products, heat treatment is more effective than traditional canned goods or glass jars for flavor, nutrients, and texture. Due to heat distribution, retort pouches retain the food's natural color and appearance, making them a favored packaging option among food industry manufacturers.

Uses of Retort Pouches

Retort pouches are used in a range of applications, but most predominantly, they are used in the food sector. These pouches for food storage contain a variety of food products. They are found in baby and toddler food, camping food, and field rations. Certain fish products, instant noodles, and "space food" are also contained in retort pouches. Sports nutrition also uses retort pouches, and this technology is behind popular products like Capri-Sun and Tasty Bite. The advantages of retort pouches are food security and convenience in storage. Retort is commonly used for applications including:

Retort Food

There are many single-serve food applications for pre-cooked meals. Soup, stews, and sauces that use retort pouches, and the convenience. Along with storage and safety benefits, it makes retort appeal to the ready-to-eat segment.

Beverage Packaging

Many blendable beverages like soups, smoothies, and energy drinks are packaged in pouches. It gives the advantage of retort processing to ensure shelf life without preservatives. Even where shelf-stability and displacement are not a factor.

Pet Food Packaging

Retort pouches are common in the packaging of pet foods. They provide a cost-effective, hygienic, and stable solution for storing wet-canned type food for pets. Pet lovers are always concerned about the quality of food. Globally, cats, dogs, chickens, and horses are mostly kept as pets.

Baby Food

Retort pouches are also very common for packaging baby food, as parents desire a sterile, safe, and convenient option for long shelf-stable food options.

Canned Food

Canned food can often have focus issues with rusting or leaching; pouches generally provide a reliable, sterile enclosure. Retort pouches are important to food safety. The amount of time to retort food will eliminate pathogenic and spoilage microorganisms. As well as provide some type of cooking or temperature interaction with the food in a pouch-style package.

Technological Difficulties and Improved Solutions

Even with their advantages, there are technological difficulties in the establishment of retort pouches. One of the primary obstacles is the ability to endure the heat of the retort process without compromising the packaging. The need for high-barrier properties to pack food requires advanced laminates and coatings.

Innovative remedies, such as multi-layer laminations and metalized films (for example, Mylar), have played an important role in addressing these challenges. These films provide both barrier properties and strength characteristics that allow pouches to be used inside the pressure and heat of the retort process.

Furthermore, lamination technology is utilized. So that pouches retain their integrity over extended periods. While providing consumers with a durable, high-quality packaging solution.

The Future of Retort Pouches

As the demand for greater sustainability and cost-effective packaging increases, retort pouches should be an important part of the future of food packaging. Their versatility, convenience, and extended shelf life make retort pouches an appealing option for food manufacturers and consumers.

As the industry continues to innovate in the area of packaging material coatings, and remains mindful of sustainability. Retort pouches should continue to be a substantive part of the fabric of packaging.

Benefits of Retort Pouches

Easy To Carry

As compared to boxes, cans, and glass jars, these are a more secure option. Its vacuum seal property makes pouch packaging unique.

Longer Shelf Life Without Refrigeration

Retailers love products that can be stored on shelves for months at a time, waiting to be used without needing refrigeration - and that comes in handy in just about all industries and all types of markets.

Reduced Shipping & Storage Costs

When compared to jars and cans, sterilized pouches are:

1. 30-40% lighter (so shipping is less expensive)

2. Flexible & compact (therefore space efficient)

3. Durable and will be minimally damaged when shipped

Convenience for Consumers

Consumers in all countries around the world value packaging that is:

+ Easily opened & resealable

+ Portable and unbreakable

+ Microwave & boil safe

Branding & Shelf Appeal

Unlike plain metal cans, flexible food pouches can have bright printed designs for package appeal. It is a fantastic way to attract customer attention on the shelf.

Cross-Industry Versatility

Flexible retort packaging can be used across a multitude of industries, from foodservice brands to pet food producers and pharmaceutical manufacturers.

Retort Pouches vs. Traditional Packaging

| Retort Pouches vs. Traditional Packaging |

| Feature |

Retort Pouches |

Cans & Jars |

|

Shelf Life

|

6–24 months

|

12–18 months

|

|

Weight

|

Lightweight

|

Heavy

|

|

Durability

|

Flexible, tough

|

Fragile

|

|

Shipping Costs

|

Lower

|

Higher

|

|

Branding Options

|

Full-color prints

|

Labels only

|

|

Consumer Convenience

|

Easy open, resealable

|

Requires opener

|

Why Choose Retort Pouches?

Picking a packaging while your product is food can be tricky and risky. You need to keep many things in mind while picking the packaging that sells and avoids spoilage. Retort bags are the solution to many problems of food preservation. Just as, vacuum, moisture resistance, and heat capacity. These three are the major factors to keep in mind while picking the best pouch.

Cost-Effective

They are more cost-effective than glass jars, metal cans, and boxes. Retort pouches not only cost you less money but also let you sleep with the assurance of quality. The vacuum property of retort pouches sets them apart.

Convenience Foods

It has a rising demand, as the world is moving faster with no time for self. These pouches let you save time. You can save the food with quality to be used later.

Pet Nutrition

In the US market, consumers spend more than $50 billion each year on pet food. And most importantly are turning towards retort pouches in order to prevent spoilage.

Healthcare Growth

More accurate solutions are required in the healthcare system. So that nothing pays more than health. Sterile packaging of nutraceuticals and pharmaceuticals continues to grow with retort bags.

Sustainability Solutions

Conventional retort bags consist of several laminated layers, which are not easily recyclable. But, at LabelPouches, we are doing things differently with:

1. Mono-material constructions (entirely PP or PE) for simplified recycling

2. Biodegradable and compostable films for more environmentally friendly options

3. Lightweight packaging formats that already minimize carbon emissions during transportation

What Sets Labelpouches Apart?

As your branding partner, LabelPouches, we are providing you the customization according to the market demand and your brand recognition. We are always a message away. Your journey to skyrocket your sales starts with us.

Affordable For Small or Big Companies

You can save money on printing because label pouches allow you to use the same base pouch design and swap the labels for each flavor or product. This economical approach is helpful for smaller companies or product testing.

We offer unbeatable prices that can’t be beat.

Flexibility In Design

There’s more flexibility to change the label than there is to change the design of a fully printed pouch packaging. A label makes it extremely easy to take advantage of promotions, limited editions, or seasonality.

Professional Look

Even with a high-quality pouch and a well-designed label, it looks professional. It allows your product to look appealing on the shelf at a fraction of what full custom-printed pouches would cost you.

Faster Processing Time

Label pouches can be quicker to build than fully printed pouches. This is advantageous when you need a quick turnaround for a launch or resupply of a product.

Less Inventory Risk

If you’re not tied into specific runs of one printed pouch. There’s less risk of wasting printed packaging if a product changes or is discontinued.

Eco-Friendly Options

Many label pouches are offered in recyclable/compostable materials. That often helps with your “green” packaging goals.

Great branding starts with smart packaging and sustainability!

Is A Retort Pouch The Right Choice For You?

We not only design and customize but also check the right product packaging that fits your brand. Our team tests all major issues regarding the product and suggests what works best for your product.

Instant Quote

Flexible retort packaging is being adopted in the U.S. market. Being a safe, practical, and consumer-friendly alternative to cans and boxes. Retort pouches are allowing companies to better meet consumer demand and stay competitive. Partner with LabelPouches, and we guarantee compliance with FDA regulations, material performance, and sustainability.

Let's keep the earth GREEN!

We are a message away from uplifting your brand and enjoying a higher ROI. Contact us and get an instant quote NOW!

Frequently Asked Questions

Q1: Are retort pouches approved by the FDA?

A: Yes, major suppliers use material that either has FDA approval or is suitable for direct food and pharma contact. They are not harmful.

Q2: What is the shelf life of retort products?

A: The shelf life can vary, but is typically 6 to 24 months based on the specific product.

Q3: Can I microwave a retort pouch?

A: Yes, most retort pouches are heat-resistant and boiling safe.

Q4: Are retort pouches recyclable in the US?

A: Traditional laminates generally are not recyclable because they are harder to recycle, but increasingly in recent years, mono-material retort pouches are showing more sustainability.

Q5: What industries can benefit from retort packaging?

A: Most retort benefits can be seen from food manufacturers, pet food, pharma, military, and outdoor meals.